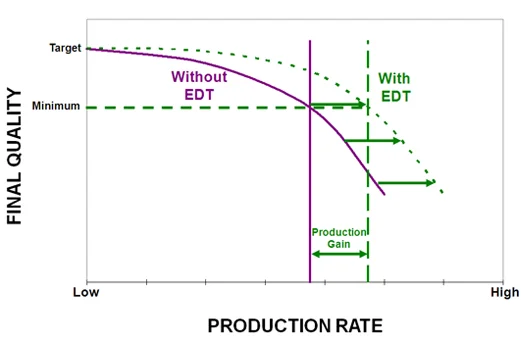

Increased Production

All production processes have output limits. These are not clear-cut numbers, but rather tonnage zones through which negative events occur that prevent mills from producing more. One such event is reduced quality. For a mill to produce more, it has to treat stock faster for a shorter duration or treat for the same duration at higher consistency. In either scenario, negative impacts to quality can be the limit.

EDT’s treatments provide quality improvements through new approaches such that higher output levels can frequently be attained. For example, quality improvements due to enhanced ink detachment and removal using EDT’s Enzynk® treatments have helped deink plants increase output from 5-15% while still meeting quality goals.

EDT’s EnzOx® treatments to reduce organic extractives-related problems have enabled machines to run faster without the associated breaks and downtime that would otherwise have been experienced. Still other mechanical production limitations due to dewatering rates can be debottlenecked through the enhanced drainage provided by EDT’s fiber modification treatments.

Most important, all of these approaches to increased production are possible without additional capital investment.